- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Flash version

© UniFlip.com

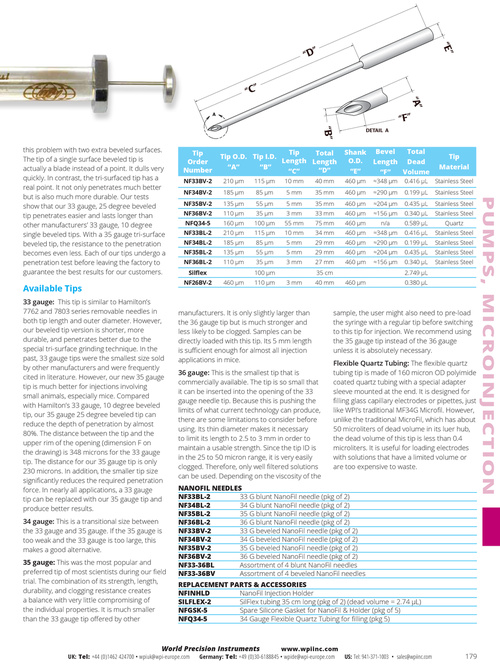

“E”

“D”

“C”

A

“F”

“A”

“B”

DETAIL A

this problem with two extra beveled surfaces. The tip of a single surface beveled tip is actually a blade instead of a point. It dulls very quickly. In contrast, the tri-surfaced tip has a real point. It not only penetrates much better but is also much more durable. Our tests show that our 33 gauge, 25 degree beveled tip penetrates easier and lasts longer than other manufacturers’ 33 gauge, 10 degree single beveled tips. With a 35 gauge tri-surface beveled tip, the resistance to the penetration becomes even less. Each of our tips undergo a penetration test before leaving the factory to guarantee the best results for our customers.

Tip Order Number

NF33BV-2 NF34BV-2 NF35BV-2 NF36BV-2 NFQ34-5 NF33BL-2 NF34BL-2 NF35BL-2 NF36BL-2 Silflex NF26BV-2

Tip Total Tip O.D. Tip I.D. Length Length “A” “B” “D” “C”

210 μm 185 μm 135 μm 110 μm 160 μm 210 µm 185 µm 135 µm 110 µm 460 µm 115 μm 85 μm 55 μm 35 μm 100 μm 115 µm 85 µm 55 µm 35 µm 100 µm 110 µm 3 mm 10 mm 5 mm 5 mm 3 mm 55 mm 10 mm 5 mm 5 mm 3 mm 40 mm 35 mm 35 mm 33 mm 75 mm 34 mm 29 mm 29 mm 27 mm 35 cm 40 mm

Total Shank Bevel O.D. Length Dead “E” “F” Volume

460 μm 460 μm 460 μm 460 μm 460 μm 460 µm 460 µm 460 µm 460 µm 460 µm ≈348 µm ≈290 µm ≈204 µm ≈156 µm n/a ≈348 µm ≈290 µm ≈204 µm ≈156 µm 0.416 µL 0.199 µL 0.435 µL 0.340 µL 0.589 µL 0.416 µL 0.199 µL 0.435 µL 0.340 µL 2.749 µL 0.380 µL

Tip Material

Stainless Steel Stainless Steel Stainless Steel Stainless Steel Quartz Stainless Steel Stainless Steel Stainless Steel Stainless Steel

PUMPS, MICROINJECTION

Available Tips

33 gauge: This tip is similar to Hamilton’s 7762 and 7803 series removable needles in both tip length and outer diameter. However, our beveled tip version is shorter, more durable, and penetrates better due to the special tri-surface grinding technique. In the past, 33 gauge tips were the smallest size sold by other manufacturers and were frequently cited in literature. However, our new 35 gauge tip is much better for injections involving small animals, especially mice. Compared with Hamilton’s 33 gauge, 10 degree beveled tip, our 35 gauge 25 degree beveled tip can reduce the depth of penetration by almost 80%. The distance between the tip and the upper rim of the opening (dimension F on the drawing) is 348 microns for the 33 gauge tip. The distance for our 35 gauge tip is only 230 microns. In addition, the smaller tip size significantly reduces the required penetration force. In nearly all applications, a 33 gauge tip can be replaced with our 35 gauge tip and produce better results. 34 gauge: This is a transitional size between the 33 gauge and 35 gauge. If the 35 gauge is too weak and the 33 gauge is too large, this makes a good alternative. 35 gauge: This was the most popular and preferred tip of most scientists during our field trial. The combination of its strength, length, durability, and clogging resistance creates a balance with very little compromising of the individual properties. It is much smaller than the 33 gauge tip offered by other

manufacturers. It is only slightly larger than the 36 gauge tip but is much stronger and less likely to be clogged. Samples can be directly loaded with this tip. Its 5 mm length is sufficient enough for almost all injection applications in mice. 36 gauge: This is the smallest tip that is commercially available. The tip is so small that it can be inserted into the opening of the 33 gauge needle tip. Because this is pushing the limits of what current technology can produce, there are some limitations to consider before using. Its thin diameter makes it necessary to limit its length to 2.5 to 3 mm in order to maintain a usable strength. Since the tip ID is in the 25 to 50 micron range, it is very easily clogged. Therefore, only well filtered solutions can be used. Depending on the viscosity of the

sample, the user might also need to pre-load the syringe with a regular tip before switching to this tip for injection. We recommend using the 35 gauge tip instead of the 36 gauge unless it is absolutely necessary. Flexible Quartz Tubing: The flexible quartz tubing tip is made of 160 micron OD polyimide coated quartz tubing with a special adapter sleeve mounted at the end. It is designed for filling glass capillary electrodes or pipettes, just like WPI’s traditional MF34G Microfil. However, unlike the traditional MicroFil, which has about 50 microliters of dead volume in its luer hub, the dead volume of this tip is less than 0.4 microliters. It is useful for loading electrodes with solutions that have a limited volume or are too expensive to waste.

NANOFIL NEEDLES NF33BL-2 33 G blunt NanoFil needle (pkg of 2) NF34BL-2 34 G blunt NanoFil needle (pkg of 2) NF35BL-2 35 G blunt NanoFil needle (pkg of 2) NF36BL-2 36 G blunt NanoFil needle (pkg of 2) NF33BV-2 33 G beveled NanoFil needle (pkg of 2) NF34BV-2 34 G beveled NanoFil needle (pkg of 2) NF35BV-2 35 G beveled NanoFil needle (pkg of 2) NF36BV-2 36 G beveled NanoFil needle (pkg of 2) NF33-36BL Assortment of 4 blunt NanoFil needles NF33-36BV Assortment of 4 beveled NanoFil needles REPLACEMENT PARTS & ACCESSORIES NFINHLD NanoFil Injection Holder SILFLEX-2 SilFlex tubing 35 cm long (pkg of 2) (dead volume = 2.74 µL) NFGSK-5 Spare Silicone Gasket for NanoFil & Holder (pkg of 5) NFQ34-5 34 Gauge Flexible Quartz Tubing for filling (pkg 5)

UK: Tel: +44 (0)1462 424700 • wpiuk@wpi-europe.com

World Precision Instruments

www.wpiinc.com Germany: Tel: +49 (0)30-6188845 • wpide@wpi-europe.com

US: Tel: 941-371-1003 • sales@wpiinc.com

179