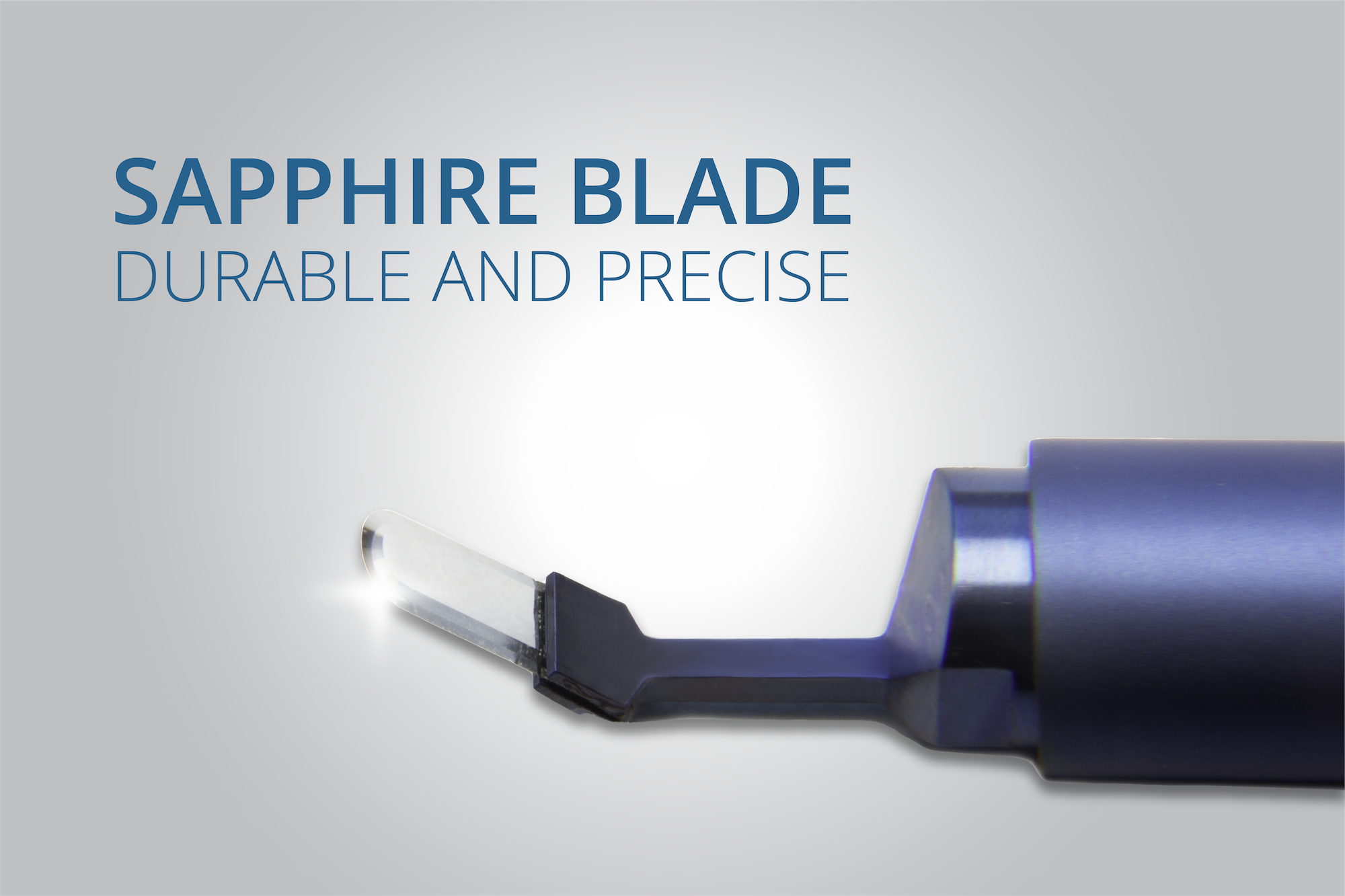

Sapphire Blades are a precise and durable solution for use in microsurgery, dissection, and related applications.

How are Sapphire Blades Manufactured?

Sapphire blades are created using a chemical process which forms an artificial sapphire. The sapphire has a hardness value of 9 on the Mohs hardness scale, slightly below the hardest mineral on earth- the diamond. This characteristic provides supreme durability and sharpness to the blade.

Why Choose a Sapphire Blade?

|

Ultra Sharp The sapphire blade's ultra sharp edge creates fine and precise cuts that prevent tissue damage and promote faster healing with less scarring. |

|

|

Easier Use The sapphire knife's ergonomic grip offers an easier grasp and is designed to be used with WPI's blades. |

|

|

Longer Lasting The blade's chemical composition provides a durable edge that lasts longer than steel surgical instruments, saving costs for your practice. |

|

|

Greater Precision The blade's sharp point and transparent finish allows greater precision in hair restoration, opthalmic microsurgery, or cosmetic procedures. |

|

|

Sterilization Versatility Sapphire blades may be sterilized using any currently known procedure. The blades are corrosion free and resistant to saline solution. |

When handled with care, the sapphire blade can last for over 100 fine and precise cuts.

Purchase a sapphire blade here:

If you have any questions, please contact us.

Request

Catalogue

Chat

Print