Micromanipulators

Whether you are looking for a motorised, remotely controlled, manual, miniature or a budget manipulators, WPI carry a wide range of micromanipulators & should have something that meets your requirements.

Micromanipulators are used when precision work is conducted under a microscope. A micropipette, electrode or probe can be mounted on a micromanipulator and move as little as a micron at a time. This tool can be used for in vitro fertilization, patch clamp experimentation, extracellular recording, microinjection and any application requiring fine mechanical placement (resolution).

In addition to micromanipulators, WPI offers tilt bases, piezo translators and a variety of stands.

Guide to Micromanipulators

Micromanipulators are an important tool used to execute minute, fine-tuned movements critical for various applications including microinjection into cells or tissue, microscopy, as well as for research involving biological and nano-engineering implementation. Before selecting a micromanipulator, consider the following to choose the best option for your application:

Micromanipulator Application and Requirements

Identify the specific movements you need the micromanipulator to perform. Different applications may demand certain properties, such as level of precision, configurations (range of movement along an x, y, z, or even a fourth dimensional axis), or external controller functionality.

Micromanipulator Precision and Accuracy

Micromanipulators vary by their level of precision, often referred to in terms of resolution. Greater resolution allows you to achieve incredibly small increments of movement per turn of the manipulator dial, essential for many micron- and nano- scale applications.

Micromanipulator Configurations/Range of Motion

The necessary operation range is an important factor when choosing the right micromanipulator. Be sure to assess your working area and set-up. Are you using a micro syringe or glass capillary? What is the length of each of these components versus the distance to your base target position? Are you performing micro-soldering? Tetrode arrays? What is the extreme angle you are working at?

While some micromanipulators are made to perform fine linear movements, others offer rotational, 3-dimensional, or even a virtual 4-dimensional movements. Further, some micromanipulators are offered with an adjustable base to alter your working angle, a beneficial feature especially when needing to access difficult configurations in any micro-engineering work. Additionally, be sure to assess whether you require a left/right-handed configuration, or if you require a dual set-up.

Micromanipulator Control System

Micromanipulators can be operated manually, with an external trigger system (for example, a computer), an isolated or integrated controller system (for example, a motorized micromanipulator), or a combination. To minimize error, it is often best to avoid manual manipulation if you require sub-micron movements.

Micromanipulator Load Capacity

How much force will be applied during your application? For example, will you be drilling into a medium that will resist the manipulator? Identify the load or force that the manipulator will endure to choose the appropriate model to avoid overloading and damaging the device.

Micromanipulator Compatibility

Be sure that the micromanipulator you choose fits into or onto your working area, whether it is being used on a bench space, or attached to a larger system. If your manipulator is too large, for example, this may interfere with your visibility when working under a microscope.

Micromanipulator Flexibility and Versatility

Determine whether you will be using your micromanipulator in various set-ups, and how it may be adapted. Can you use your manipulator both left and right-handed? If working on a pressure-adjusting microscope or tabletop, the placement of a micromanipulator must be carefully determined. What future projects may alter how you use your micromanipulator? These factors are important when considering which is the right micromanipulator for you!

Micromanipulator Stability and Vibration Control

Like the previously mentioned stabilizing microscope or tabletop set-ups, some applications require the micro manipulation set-up to account for any de-stabilizing environmental factors like room pressure or temperature change, or external vibration. Maintaining stability is of utmost importance for achieving the best possible results for any application sensitive to minute deviations in surface stability. Be sure to consider models that offer vibration isolation or damping features to minimize external movement of your micromanipulator.

Manual Manipulators

WPI offers affordable and high-end micromanipulators for use in research laboratorie...

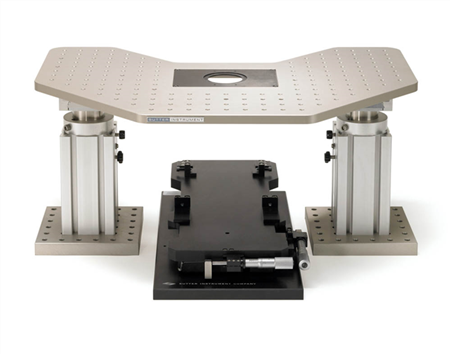

Stands/Accessories

See our selection of stands and magnetic bases for use with manipulators in research...

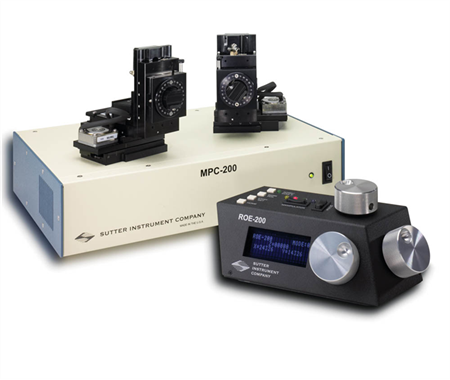

Motorised Manipulators

Our range of motorized Micromanipulators offer precision movement on a variety of ax...

Stages & Translators

WPI offers a range of stages and translators for manipulators to be easily incorpora...

Request

Catalogue

Chat

Print