Science and Art of Pulling Micropipettes

Pulling capillary glass into micropipettes or microelectrodes is a science and an art. Not only must you understand the environmental factors and the physics affecting each pull, but you must also know how to tweak your program to pull tips of consistent shape and size. Glass micropipettes or microelectrodes are used in intracellular recording, patch clamp, microperfusion, and microinjection. Let’s look at some factors that can affect the pulling of glass and how to adjust a program to get the micropipettes you need for your application.

Pullers like WPI’s entry level, research-grade PUL-1000 (a microprocessor controlled, four-stage, horizontal puller) are designed with tight mechanical specifications and precision electronics for complete control of the pulling process and accurate reproducibility. The PUL-1000, like many other pullers on the market, offers programmable sequences of up to four steps with heat indexing, force (g), movement, and cooling time. This allows graduated cycles for a variety of applications. |  |

Types of Heat Affecting a Pull

The glass transition is the gradual and reversible transformation from a hard and relatively brittle solid state into a soft and viscous state as the temperature increases. To form glass into certain shapes using a puller, heat is applied through a filament. There are three methods to transfer heat from a filament to a glass capillary:

- Radiation

- Direct conduction in solids

- Convection of air

The filament is heated when current passes through it. The heat radiating from the filament to the glass is the primary heat source affecting the capillary glass transition, and the distance between the surface of the glass and the surface of the filament determines the amount of heat transferred. That is the reason why it is important to make sure the glass is placed at the center of the filament. All facets of glass should be heated evenly.

However, the radiant heat is not the only source of heat in a puller. The filament block that holds the filament is also heated as the filament warms. The heat from the surface of filament is conducted to the filament holders. While the temperature of the filament may remain relatively consistent, as the puller use continues, the temperate of the filament holders increases, which can affect the results of a pull. To reduce heat built-up both in the filament and the filament holders, allow time for the colder ambient air to cool the filament and the filament holders between pulls.

Finally, the convection of air in the ambient environment (both inside and outside of the cover chamber) affects the heat transfer from the filament to the glass. So, room temperature and humidity affect the glass transition. If the room temperature is cooler or warmer, your resulting micropipettes may vary, even when you are using the same pulling program.

Effect of the Platinum/Iridium Heating Filament Changes Over Time

The filament is made of a platinum/iridium alloy. Even though platinum/iridium alloy is one of the most inert substances in heating materials, it is still slowly oxidized by the oxygen from air. The mass of platinum/iridium alloy is reduced as the puller is used, and it will eventually burn out. As it slowly deteriorates over time, the temperature of the filament in use changes.

Type of Glass Affects a Pull

Different glass capillaries with different outside diameters (OD) vary in their glass softening points (melting point temperatures). Variations of glass constituents among different glass capillary products show variations in their softening points. There may even be some variation of the softening points of the same glass capillary products taken from different lots. This is to be expected with any standard manufacturing deviation(s).

How to Fine Tune a Programmed Pulling Sequence

Some of our glass capillary pulling sequences and results are shown in the PUL-1000 Cookbook. You may need to make some fine adjusts of the pulling sequence parameters based on the glass capillary product you use and taking into account your laboratory environmental conditions like temperature and humidity.

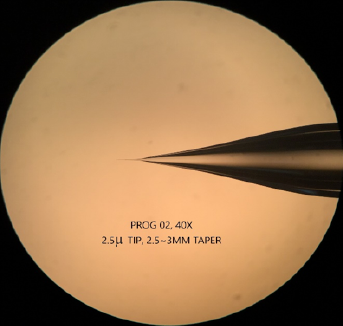

As a rule of thumb, the parameters (Heat, Force, Distance, and Delay) can be altered to achieve desired shapes and dimensions of pre-pulled pipettes. The table below shows basic guidelines for setting up a sequence. You can see how increasing or decreasing the parameter will affect the pre-pulled pipette shapes and dimensions.

| Parameter | Increase | Decrease |

Heat | Longer Taper | Shorter Taper |

Force | Smaller Tips, Longer Taper | Larger Tips, Shorter Taper |

Distance | Smaller Tips | Larger Tips |

Delay | Shorter Taper | Longer Taper |

NOTE: To make a larger OD tip, gently, and incrementally reduce the tip, checking its size and integrity. Use a breaking back technique with blades or tweezers, or drag the tip over a Kimwipe. A second process such as beveling or fire polishing may also be needed. Aggressive trimming may result in an undesirably large OD.

Art of Pulling Glass

By pulling your own glass, you can customize your micropipettes and microelectrodes to get exactly what you need. Micropipette glass pulling is both a scientific technique and an art form due to the precise control required to create highly specific and delicate instruments used in fields like neuroscience, cell biology, and electrophysiology. Behind every successful pull is a proper understanding of material properties, heating, and mechanics, ensuring that the micropipettes meet specific technical requirements for experiments. The art lies in the skillful adjustment of the micropipette puller and the ability to create pipettes that not only meet technical specifications but also perform optimally for highly specialized and delicate tasks. The balance of both ensures that the micropipettes produced are functional, consistent, and tailored for high-precision scientific work.

DMZ Universal electrode puller

The DMZ-Universal-Electrode-Puller consists of an unique pulling mechanism which was...

Request

Catalogue

Chat

Print