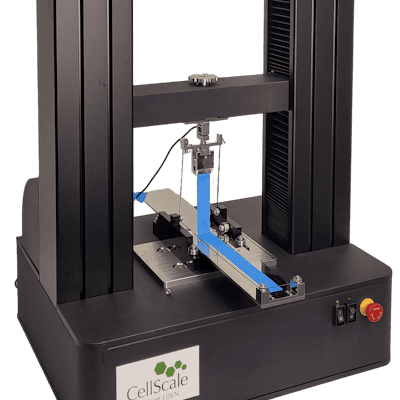

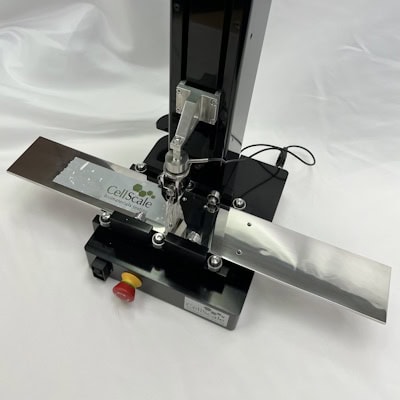

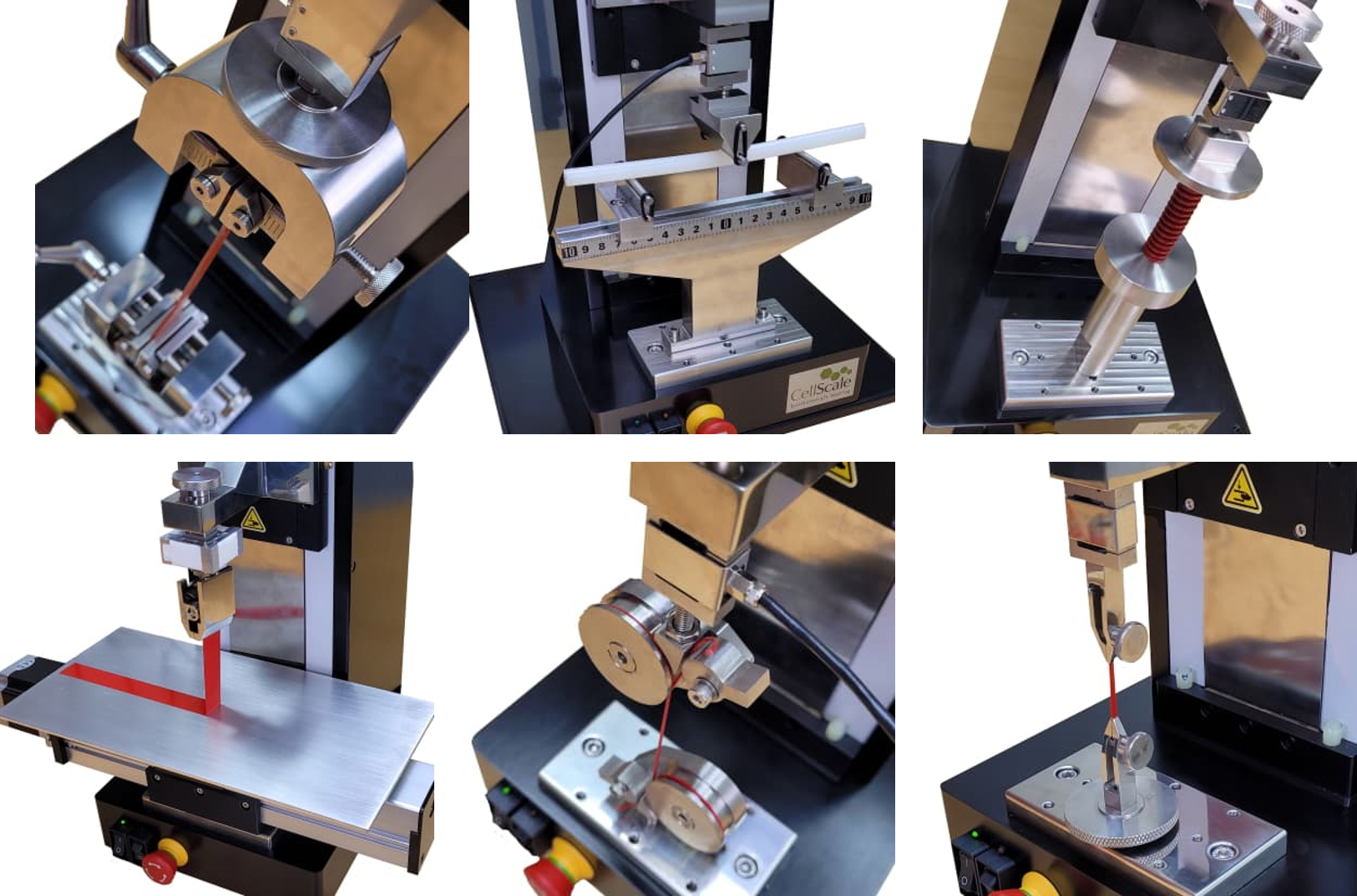

Mechanical Testing - UniVert

Mechanical testing when and where you need it for tension, compression and bending testing

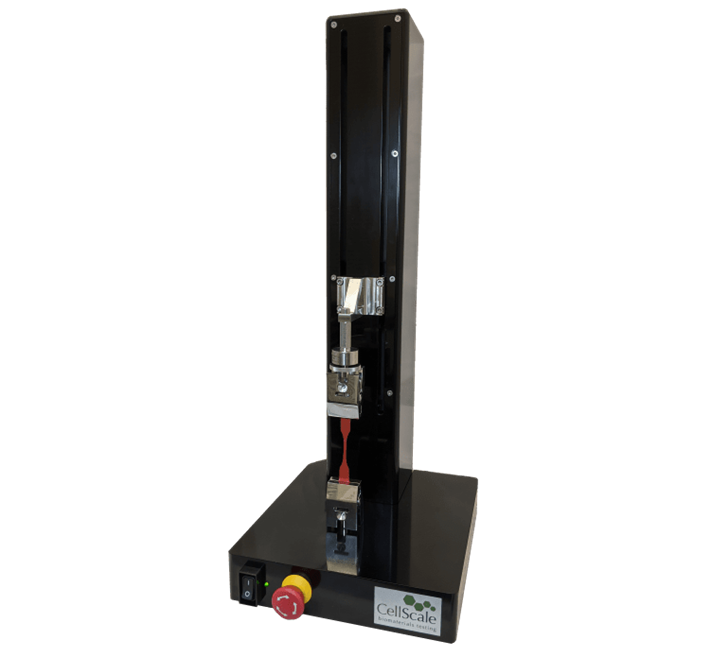

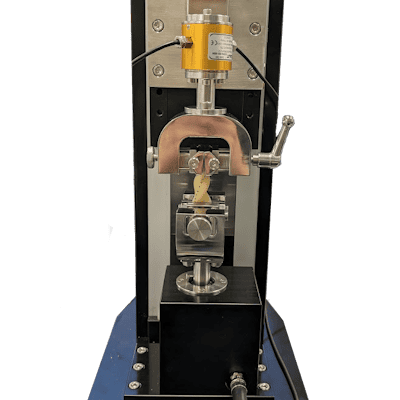

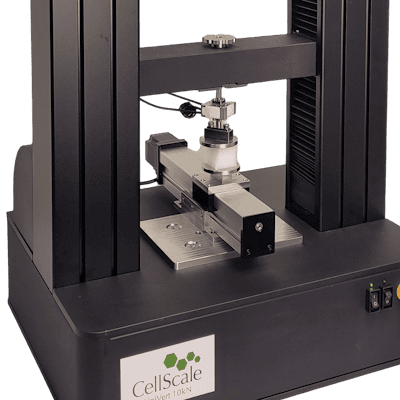

The UniVert universal material testing machine provides critical mechanical property data for research in natural tissues, 3D bio-printed structures, orthopedic devices, and more.

The compact size and budget-friendly price of the UniVert S makes it possible to access testing capabilities exactly when and where they’re needed. The larger force capacities and extended range of the UniVert 1kN and 10kN are suitable for a wide range of materials.

Key Features

- Quality, cost-effective testing in a small package

- User-friendly with easy-to-change fixtures and load cells for various applications

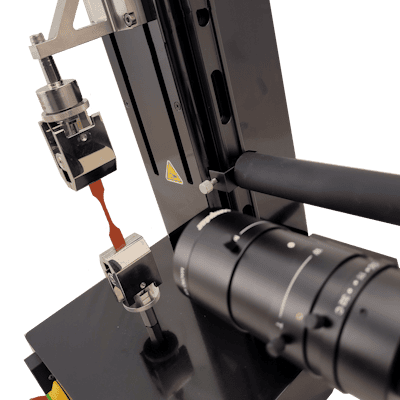

- Integrated imaging for test visualization, analysis, and presentation

- Comprehensive user interface software for straightforward, cyclic, relaxation, and multi-modal testing with immediate feedback

- Integrated environmental chambers

- Optional secondary axes for shear, torsion, or pressure testing

Specifications

| UniVert S (S2) | UniVert 1kN | UniVert 10kN | |

|

|

|

|

| Dimensions (cm) | 22 x 22 x 54 | 30 x 22 x 60 | |

| Weight (kg) | 8 | 20 | |

| Force Capacity (N) | 200 | 1,000 | 10,000 |

| Load Cells (N) | 0.05-200 | 0.05-1000 | 0.05-1000 |

| Force Accuracy | 0.2% of load cell capacity | 0.2% of load cell capacity | 0.2% of load cell capacity |

| Travel (mm) | 300* | 300* | 800* |

| Max Velocity (mm/s) | 20 (100) | 20 | 20 |

| Max Acceleration (m/s2) | 1 (2) | 1 | 1 |

| Max Cycle Frequency (Hz) | 2 (10) | 2 | 2 |

| Max Data Rate (Hz) | 100 (500) | 100 | 100 |

*Longer stroke available on request

Applications

Tension

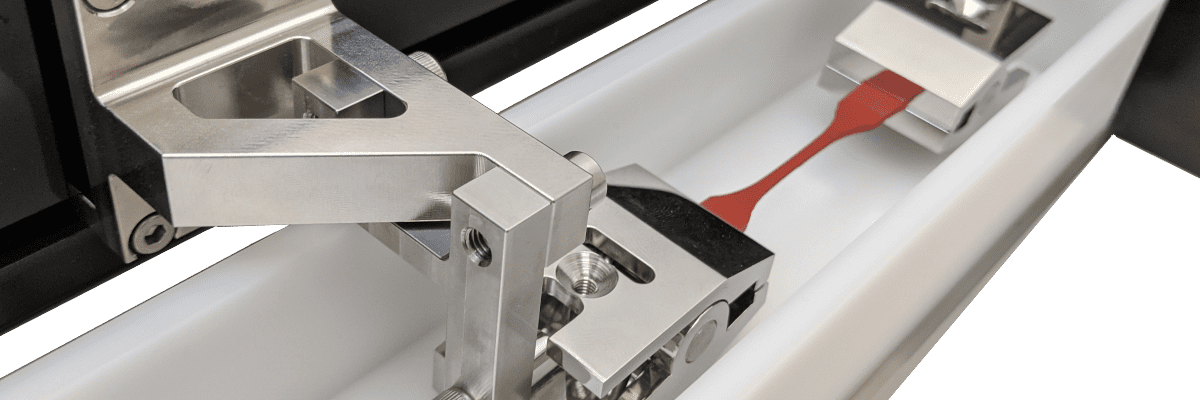

Specimens are typically clamped and pulled at a defined displacement rate while force/displacement data is captured. Force-controlled testing and cyclic testing are also common.

Unique to Biomaterials

Specimens must be fixed to the tester without causing damage at the attachment site. Biomaterials are often soft, slippery, or have irregular shapes and require specialized fixtures to achieve optimal results.

Most biomaterials testing applications require image-based measurement techniques to directly measure specimen geometries and strain values.

Common Applications:

- Muscle, skin, and tendon tissues

- Blood vessels

- Plant structures

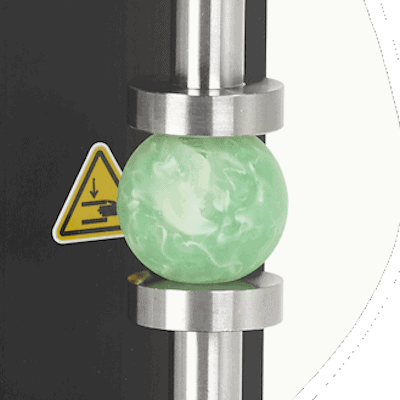

Compression Testing

Parallel plate compression involves crushing a specimen that typically has flat, parallel upper and lower surfaces and a constant cross section. Variations include indentation (spherical or other geometries), puncture, and burst testing.

Unique to BiomaterialsTime-correlated images are helpful to understand test results, especially if the specimen geometries are irregular or material properties are non-homogeneous.

Very small fixtures and low-force sensors are commonly used with the UniVert to test small delicate materials. The MicroTester is optimized for for even smaller specimens and can achieve force resolutions of 10nN.

Common Applications

- Hydrogels

- Bone

- Cartilage

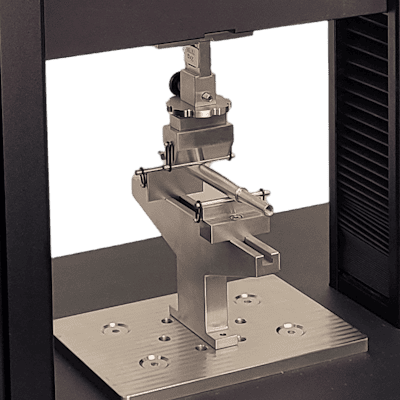

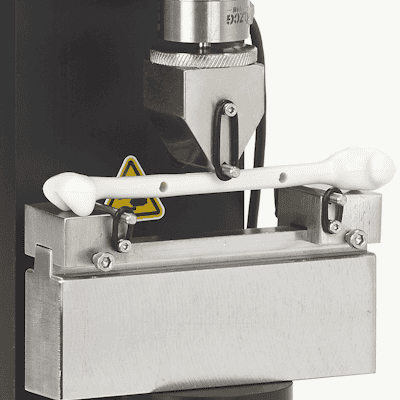

Bending

Specimens are typically long and thin and are supported at each end by fixed supports. Load is applied at 1 or 2 points between the fixed supports for 3 or 4 point testing. This is often a test to failure.

Unique to Biomaterials

The irregular shapes and variability in biological structures require appropriate fixtures, protocols, and expertise to ensure reliable data. Time-correlated images are helpful to understand test results, especially if the specimen geometries are irregular or material properties are non-homogeneous.

For very delicate specimens such as plant fibers or small tissues, the MicroTester highly suitable and can achieve force resolutions of 10nN.

Common Applications

- Rodent long bones

- Orthopaedic devices

- Plant structures

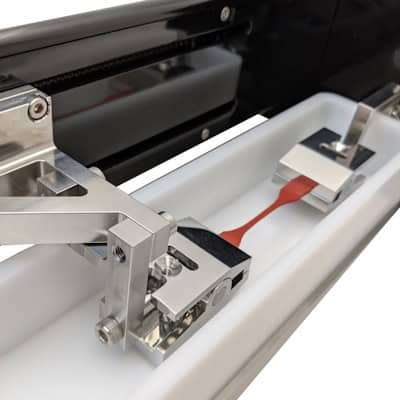

Peel & Shear

Peel testing is used to characterize the strength of the adhesion of one material to another. Shear testing to characterize a material’s response to shear loads or the adhesion strength of one material to another with a shear load.

Unique to Biomaterials

Biomaterials are often soft, slippery, or have irregular shapes and hence require specialized fixtures to achieve optimal results.

Adhesion is often affected by temperature and humidity. The UniVert can be efficiently equipped with the necessary environmental control accessories.

Common Applications

- Tapes, glues, and sealants

- Rubbers, gels, and other soft 3-dimensional materials

Fatigue / High Rate

Fatigue testing involves loading a specimen over many cycles to determine the impact on its mechanical response. Testing modalities include tension, compression, bending, and inflation, among others. High-rate testing involves loading the specimen at velocity to determine how the response of the material varies with strain rate.

Both fatigue and high strain rate testing benefit from an actuator capable of high accelerations and velocities. The UniVert system can be fitted with an auxiliary actuator to efficiently meet these requirements.

Unique to Biomaterials

This type of testing is necessary musculoskeletal and cardiovascular tissues that would normally be subjected to cyclic loading in vivo. For basic research, the test setup can be easily configured to replicate in vivo conditions. For some orthopaedic materials and applications, established test standards exist.

Common Applications

- Musculoskeletal tissues and synthetic alternatives

- Cardiovascular tissues such as arteries and heart valves

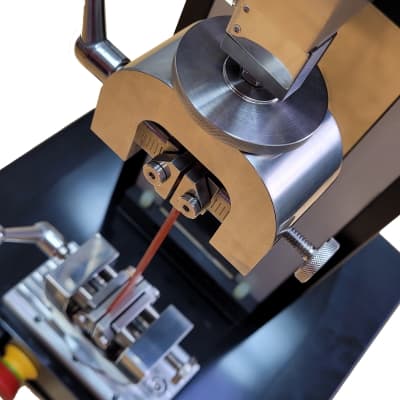

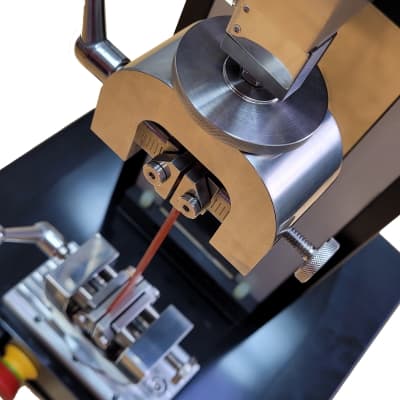

Torsion

Specimens are typically supported at each end by platens (with compressive load), grips, or jaws similar to a drill chuck. Any protocol specified in terms of axial displacement, axial force, torque, or rotation can be specified.

Unique to Biomaterials

This type of testing is often used to evaluate bones, joints, or similar synthetic materials. The UniVert system can be easily configured to match protocols used in previous research.

Common Applications

- Rodent long bones and/or joints

- Arteries

- Composite materials

Combined Loading

The UniVert is always equipped with uniaxial linear testing capabilities. In addition, it can support up to 2 additional loading mechanisms. All of these subsystems can be used simultaneously in a single test protocol. Common configurations include:

- torsion-tension (e.g. arteries)

- torsion-compression (e.g. joints)

- tension-pressure (e.g. arteries)

- compression-shear (e.g. muscle)

Less than 0.1N Force Range

The UniVert systems can be used for testing between 0.1N and 10kN. For testing below 0.1N, the use of the MicroTester system is recommended.

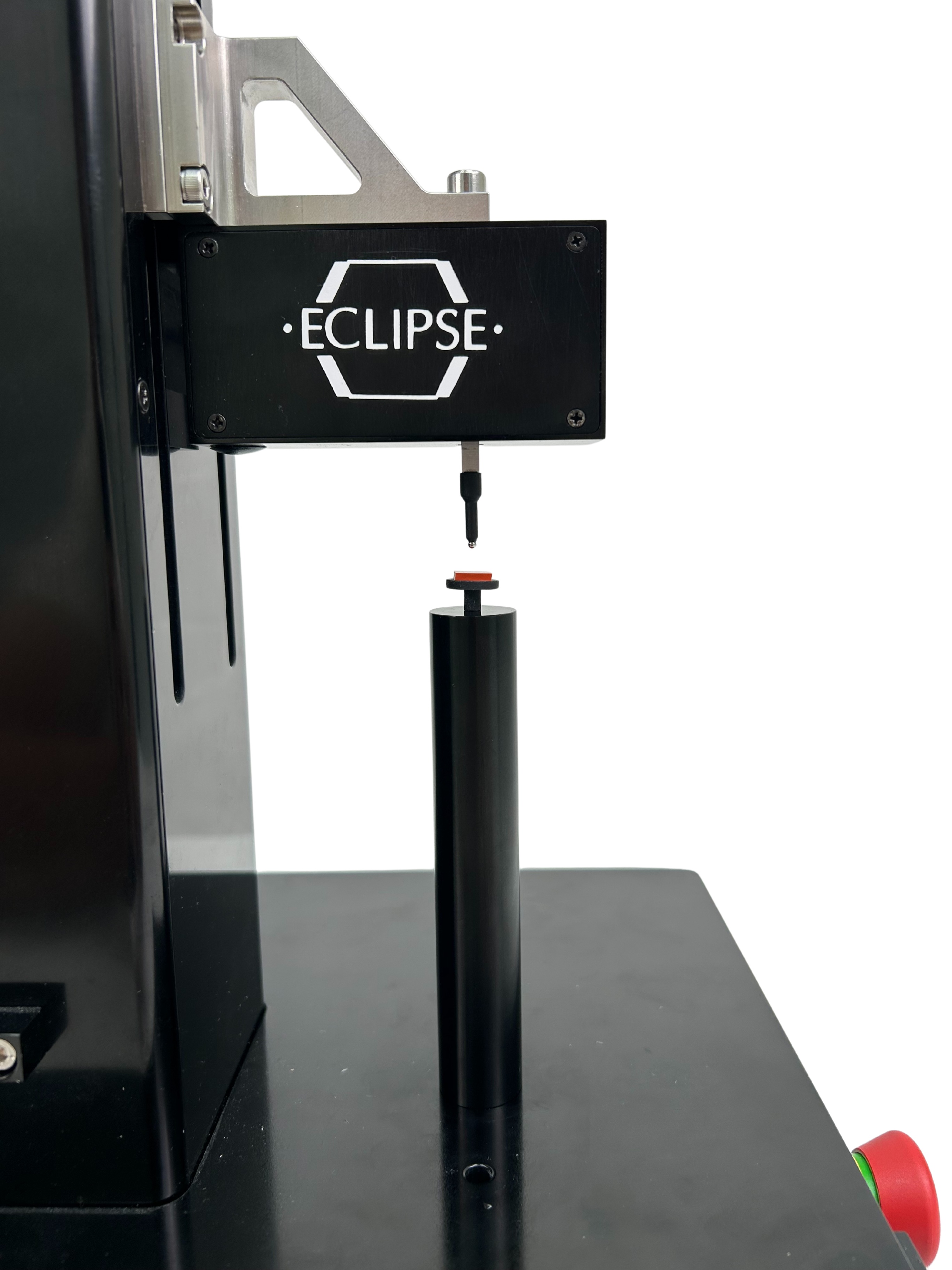

0.1 – 1 N

Discover the pinnacle of low-force measurements. The Eclipse force sensor delivers unmatched precision and accuracy for bench-top uniaxial testing, detecting forces as small as 40?µN. Built to last, this patent-pending technology features 10,000% overload protection for exceptional reliability. Paired with the UniVert system and testing platform, this is the ultimate low-force materials testing solution.

It is a robust, precise and user-friendly option for soft materials testing, perfect for tension and compression testing for hard to handle samples. The Eclipse has a compact design that offers quick setup, at easy to attach fixtures that will have you testing your samples within minutes.

Common Application

- Hydrogels

- Fibers

- BioInks

- 3D-bioprinted materials

- Tissues

- Soft polymers

- Organoids

- Meshes

- Films

1 – 10 N

In this force range, the UniVert is typically equipped with a miniature S-beam load cell and plastic fixtures to minimize the offset force. These sensors and fixtures are available for the UniVert S, 1kN, and 10kN models.

Common Applications

- Small animal tissues

- Hydrogels

- Rubbers and other compliant materials

10 – 100 N

In this force range, the UniVert is typically equipped with a miniature S-beam load cell and plastic fixtures to minimize the offset force. These sensors and fixtures are available for the UniVert S, 1kN, and 10kN models.

Common Applications

- Small animal tissues

- Hydrogels

- Rubbers and other compliant materials

.png)

100 – 1000 N

In this force range, the UniVert is typically equipped with an S-beam load cell and stainless steel fixtures to suitably support the test specimens. These sensors and fixtures can be fitted to the UniVert S (max 200N), 1kN, and 10kN models.

Common Applications

- Small specimens of all types

- Educational labs (particularly UniVert S model)

.jpg)

1000 – 10,000 N

In this force range, the UniVert is typically equipped with an S-beam load cell and stainless steel fixtures to suitably support the test specimens. These sensors and fixtures can be fitted to the UniVert 10kN models.

Common Applications

- Specimens of all types

- Departmental facilities

.png)

.png)

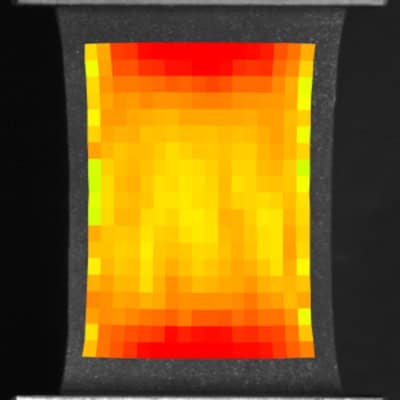

Strain Control

For any given test, the specimen may not deform as expected due to grip slipping, non-uniform material properties, or misalignment. When equipped with an upgraded imaging system, the UniVert software can measure the specimen strain is real-time by tracking features on the specimen surface. This information is used to modulate the cross head motion to achieve the strain profile prescribed in the test method. This ensures that the results of multiple tests can be easily compared and that combined loading protocols are well synchronized.

Unique to Biomaterials

Biomaterials are often more complex than other engineered materials. Using non-contact strain measurement to achieve true strain control is a powerful tool for materials characterization.

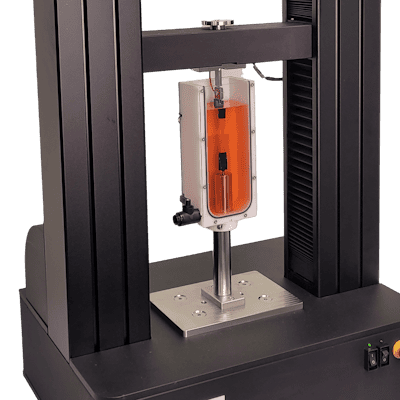

Liquid Baths

Temperature-controlled fluid liquid baths are used to maintain consistent hydration and temperature conditions when working with certain materials

Unique to Biomaterials

This type of testing is often used in musculoskeletal and cardiovascular tissues that would typically be subjected to cyclic loading in vivo. For basic research, UniVert systems can be easily customized to replicate in vivo conditions. For some orthopaedic materials and applications, established test standards exist

Common Applications

- Musculoskeletal tissues and synthetic alternatives

- Cardiovascular tissues such as arteries and heart valves

Custom Solutions

Due to the wide variety of applications within the biomaterials space, the UniVert has been carefully designed with a broad range of configurations. Even so, there is often a need for custom fixtures, controls, environmental accommodations, or other functionality. CellScale has a long history of successfully and efficiently collaborating with our customers to achieve successful research outcomes.

If you have a specialized application, we would be glad to support your research with a custom solution.

Multiple Axis Testing Upgrade

Shear, twist, and pressure axes can be added to the primary linear test axis to test a wide range of specimens. These actuators and sensors integrate seamlessly with the device controller, software and data output.

For UniVert S (UV-200-02)

To order select the UV-200-03 UniVert+ 3 axis capable upgrade and the axes required

| UV-200-03 | UniVert universal uniaxial mechanical tester three-axis capable upgrade (requires factory fitting) |

| UV-200-30S | Shear axis upgrade to the UniVert mechanical test system, includes 1 additional 3-axis load cell (requires factory fitting and UV-200-03) |

| UV-200-30T | Torsion axis upgrade to the UniVert mechanical test system, includes 1 additional tension/compression/torsion load cell (requires factory fitting and UV-200-03) |

| UV-200-30P | Pressure axis upgrade to the UniVert mechanical test system, includes 1 pressure sensor (requires factory fitting and UV-200-03) |

For UniVert 1kN (UV-1000-02) and Univert 10kN (UV-10KN-02)

To order select the UV-1000-03 UniVert+ 3 axis capable upgrade and the axes required

| UV-1000-03 | UniVert 1kN/10kN - 3 axis capable upgrade (requires factory fitting) |

| UV-1000-30S | Shear axis upgrade to the UniVert 1kN and 10kN mechanical test system, includes 1 additional 3-axis load cell (requires factory fitting and UV-1000-03) |

| UV-1000-30T | Torsion axis upgrade to the UniVert 1kN and 10kN mechanical test system, includes 1 additional tension/compression/torsion load cell (requires factory fitting and UV-1000-03) |

| UV-1000-30P | Pressure axis upgrade to the UniVert 1kN and 10kN mechanical test system, includes 1 pressure sensor (requires factory fitting and UV-1000-03) |

High Performance Upgrade

To upgrade the UniVert S to the S2 high perfomance specification including 5X speed, cycle frequency, and data rate over the UniVert add part number UV-200-02H.

The upgrade improves

- Max Velocity from 20 mm/s to 100 mm/s

- Max Cycle Frequency from 2 Hz to 10 Hz

- Max Data Rate from 100 Hz to 500 Hz

| UV-200-02H | UniVert S universal uniaxial mechanical tester S2 Performance Upgrade |

Specimens & Mounting Options

UV-1000-03

Three-axis capable upgrade for UniVert 1KN universal uniaxial mechanical tester (requires factory fitting)

UV-1000-03

Three-axis capable upgrade for UniVert 1KN universal uniaxial mechanical tester (requires factory fitting)

UV-1000-30P

Pressure axis upgrade to the UniVert 1KN mechanical test system, includes 1 pressure sensor (requires factory fitting and UV-1000-03)

UV-1000-30S

Shear axis upgrade to the UniVert 1KN mechanical test system, includes 1 additional 3-axis load cell (requires factory fitting and UV-1000-03)

UV-1000-30T

Torsion axis upgrade to the UniVert 1KN mechanical test system, includes 1 additional tension/compression/torsion load cell (requires factory fitting and UV-1000-03)

UV-200-02H

S2 High Perfomance Upgrade of UniVert specification including 5X speed, cycle frequency, and data rate over the UniVert. The upgrade improves:

- Max Velocity from 20 mm/s to 100 mm/s

- Max Cycle Frequency from 2 Hz to 10 Hz

- Max Data Rate from 100 Hz to 500 Hz

UV-200-03

Three-axis capable upgrade for UniVert universal uniaxial mechanical tester (requires factory fitting)

UV-200-30P

Pressure axis upgrade to the UniVert mechanical test system, includes 1 pressure sensor (requires factory fitting and UV-200-03)

UV-200-30S

Shear axis upgrade to the UniVert mechanical test system, includes 1 additional 3-axis load cell (requires factory fitting and UV-200-03)

UV-200-30T

Torsion axis upgrade to the UniVert mechanical test system, includes 1 additional tension/compression/torsion load cell (requires factory fitting and UV-200-03)

UV-200-11

UniVert Horizontal Temperature Controlled Fluid Bath

- For tension tests

Requires UV-200-22 connector and software upgrade

UV-200-12

UniVert Vertical Temperature Controlled Fluid Bath, 600mL Volume

- For compression tests

Requires UV-200-22 connector and software upgrade

UV-305

Replacement polymer (spring-closure) tension grips for UniVert suitable for 20N and under (1 SS & 1 polymer)

UV-315

Replacement stainless steel (combination spring/screw closure) tension grips for UniVert - suitable for 10N and over

UV-311

Brackets for BioRake grip attachment to UniVert system requires use of horizontal test orientation

UV-1000-10N

10-200N Force Package for UV-10KN-02(03)

Includes: 1 load cell (10N/20N/50N/100N/200N)

Mid force tension grips (spring and screw closure)

Mid force compression platens

UV-1000-1N

1-5N Force Package for UV-10KN-02(03)

Includes: 1 load cell (1N/2.5N/4.5N)

Low force tension grips (polymer, spring closure)

Low force compression platens (polymer)

UV-1000-200N

500-1000N Force Package for UV-1000-02(03)

Includes: 1 load cell (500N/1000N)

High force grips (screw closure) with 1 set of grip faces

High force compression platens

UV-10KN-2000N

2-10kN Force Package for UV-1000-02(03)

Includes: 1 load cell (500N/1000N)

High force grips (screw closure) with 1 set of grip faces

High force compression platens

Request

Catalogue

Chat

Print