DMZ Universal electrode puller

The DMZ-Universal-Electrode-Puller consists of an unique pulling mechanism which was developed at Institute of Physiology in Munich, Germany, allowing two identical pipettes to be pulled, with automatic fire-polishing.

- Overview

- Specifications

- Accessories

- Citations

- Related Products

Overview

The DMZ-Universal-Electrode-Puller consists of an unique pulling mechanism which was developed at Institute of Physiology in Munich, Germany. It is nearly free of any friction and precise enough to produce pipettes with a tip diameter down to 0.2 µm. Although the device pulls on only one end of the capillary glass, it is able to make both pipettes equal by re-centering the glass tube after each elongation, with fully automatic fire-polishing of the pipettes after pulling.

With this construction it is possible to produce pipettes and electrodes for a great variety of different purposes.

Additionally the device is designed to not only produce single pipettes, but to reproduce pipettes with the exact shape, taper and tip diameter immediately before use.

Features:

- Permanent Storage of 80 programs

- One- or two-staged pulling programs, in which all variables (see below) can be set independently for each stage or the option of repeating the first stage

- No risk of breaking thin-walled capillary glass in the glass holders

- Choice of capillary glass outer diameter of 1 to 2 mm.

- Free choice and absolute reproducibility of all characteristics

- Suitable for pulling injection and suction pipettes

- Suitable for pulling intracellular electrodes with a tip diameter down to 0.2 µm and a resistance up to 100 MΩ

- Fast heater retraction to avoid the need for air-jet cooling

- Exceptionally low friction and inertia thanks to the unique pulling system

- Automatic compensation for variations in the thickness of the glass

- Suitable for pulling patch-clamp pipettes with precisely defined tip (usually between 1 and 80 µm)

- The puller may fire-polish patch clamp pipettes

- It can be used to fabricate patch-micropipettes well suitable for reaching gigaseals

- A high weight of 29 kg ensures a firm stand and therefore accurate results

- Precise shape and position of the filament has, compared to other pullers, less influence on the tip size and shape of the electrode

- The excellent reproducibility of electrode tip characteristics allows producing the electrode as required, immediately before use

- The mechanism doesn't need periodical calibration

Adjustable Variables:

- Distance of pull (longitudinal)

- Pulling force (time-controlled program)

- Pulling force (distance-controlled program)

- Time- or distance controlled heating

- Heating power radiated by the filament

See the puller in action!

The following video shows how the Electrode-Puller makes two patch-clamp electrodes using program P10:

After pulling the pipettes apart, the puller keeps them in the holders to fire-polish them:

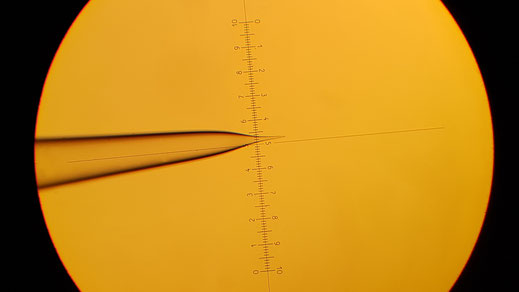

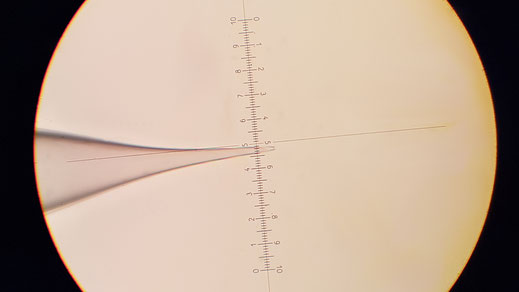

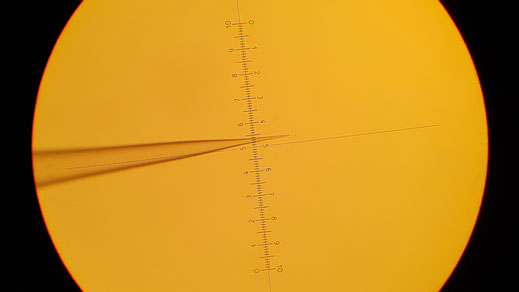

Some pipettes the puller made

Whole cell pipette with a tip diameter of 5 µm:

Patch-clamp pipette with a tip diameter of 2 µm:

SAFELY PACKAGED AND READY TO BE USED

- We ship our devices in sturdy cardboard packages, that endure the high weight of 29 kg.

- The cardboard packages are padded with custom designed upholstery to make sure that nothing breaks or becomes misaligned during transport.

- The Universal-Electrode-Puller is factory set ready to be used directly after unpacking.

- Includes a user manual, pwer cable and a spare part box containing new filaments (3 mm and 4.5 mm), 2 screwdrivers, fuses, grease, 2 holder blocks with polyurethane, different types of glass tubes and more.

Specifications

Glass types:

- Borosilicate

- Aluminosilicate

Glass dimensions:

- Min. length: 75 mm

- Min. outer diameter: 1.0 mm

- Max. outer diameter: 2.0 mm

Physical dimensions:

- Width: 48 cm

- Depth: 30 cm

- Height: 26 cm

- Weight: 29 kg

Warranty: 2 years

.png)

.png)

Request

Catalogue

Chat

Print