DGKit-1.0

Droplet Generation Kit

Includes: 2 x ExiGo pumps with PC LabVIEW control software; 2 x Flow Sensors; 2 x DropChips; Tubing and Oil

- Overview

- Specifications

- Accessories

- Citations

- Related Products

Overview

There are 3 images available to view - click to enlarge and scroll through the product gallery.

Droplet Generation Kit Brochure

/ Download as PDF

Features:

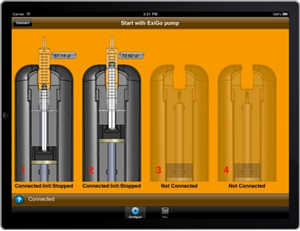

- 2 x ExiGo pumps with LabVIEW control

- 2 x Flow sensors

- 2 x DropChips

- Tubing Sets

- Oil

The ExiGo microfluidic syringe pumps use the syringes to hold the sample (oil or water phase). The flow sensors are provide active feedback of the flow control of both the oil and water phases. Fluidic capacitance in microfluidic devices can often introduce instabilities when trying to vary flow rates. Therefore, it is extremely important to have accurate microfluidic pumps with flow sensors to limit such instabilities enabling you to product uniform, stable droplets of a consistent size, volume and frequency.

Microfluidic Chip with appropriate geometry to create droplets: the geometry of the junction (where the oil and water phase meet) is the most influential factor affecting droplet size. Once this is fixed, the droplet size is affected (to a lesser extent) by surfactant concentration and the ratio of flow rates of the oil and water phases.

Stable Channel Surface Chemistry to ensure droplet stability: stabilises interface between oil and water phase giving stability to the droplets.

- Water-in-oil droplets: you will need a hydrophobic channel surface and this can be achieved by pre-filling the microfluidic chip with DropCoat

- Oil-in-water droplets: in this case, you need a hydrophilic channel surface. Cellix's DropChip channels are sold pre-treated so that the surface of the channels are hydrophilic

Surfactant: stabilises the interface between oil and water phase giving stability to the droplets.

Oil for continuous phase: surfactant is often added to the oil to improve droplet stability.

Tubing tset o connect from your pumps to the microfluidic chip

Specifications

| Volumetric Flow Rates | 0.0725 pL/minute - 20 mL/minute |

| Microsteps per one revolution of lead screw | 250,000 |

| Step resolution | 0.008μm |

| Pulse-free flow rate for microfluidic applications* | 10nL/min - 1mL/min ± 20nL/min @ 250uL glass syringe 100nL/min - 20mL/min ± 40nL/min @ 5mL plastic syringe |

| Flow rate stability for microfluidic applications* | ± 0.25% of Full Scale @ 250μL syringe and 8,000nL/min ExiGo Flow Sensor |

| Dynamic Response | 50ms max (recorded at flow rate change from 0 to 10,000nL/min) |

| Compatible Syringes | 0.5μL - 1μL (glass syringes) 1mL - 5mL (plastic syringes) |

| Working Pressure | 30 psi - 2 bars maximum |

| External Trigger | 2 inputs and 2 outputs of external trigger for operation with external units and software |

| Flow control | Reversible flow direction - Push/Pull Programmable perfusion mode: constant, ramp, step, sine |

| Additional features | Easy to use PC control. Control/program up to 4 pumps independently Wi-fi communication Standard tubing for connection to any microfluidic biochip |

| Software Control | LabView control via a PC |

| Dimensions | 225mm (W) x 69mm (D) x 122mm (H) |

| Weight | ~ 1.3kg |

| *Measured with ExiGo Flow Sensor and active PID feedback | |

Request

Catalogue

Chat

Print