IV-ECU-HOC

Stagetop Environmental Chamber and Environmental Control Unit for CO2, O2 and heat

- Overview

- Specifications

- Accessories

- Citations

- Related Products

Overview

There are 1 images available to view - click to enlarge and scroll through the product gallery.

ECU Datasheet

/ Download as PDF

STEV Datasheet

/ Download as PDF

ECU Instruction Manual

/ Download as PDF

ECU Instruction Sheet

/ Download as PDF

- Complete stagetop environment (STEV) and ECU-HOC Environmental Control Unit

- Monitor and control the CO2 and O2 flow and temperature in a microcope chamber or stagetop environment

For short term or long term studies of living cell cultures under a microscope or for time lapse video research, a microscope stagetop incubator is essential. Perfect for Live Cell Imaging, STEV (the stagetop environmental control system) is a compact environmental case that houses your culture wells and fits on a microcope stage inside the live cell microscope incubator. This system offers precision control of both temperature and carbon dioxide, as well as remote control and data logging via a USB connection. The system is flexible and easy to configure for a variety of experimental conditions. The ECU can be used to control the environment inside a microscope chamber or a STEV (stagetop environment). This system offers precision control of temperature, carbon dioxide and oxygen, as well as remote control and data logging via a USB connection. The system is flexible and easy to configure for a variety of experimental conditions. A satellite AirTherm provides heat to the chamber, which is controlled by the Environmental Control Unit (ECU). The Environmental Control Unit (ECU) houses all the electronics for:

- Regulating the CO2 and O2 flow and temperature in the chamber

- Controlling the temperature of our AirTherm Satellite or an auxiliary heater

- Monitoring the air flow, CO2 level, O2 level and temperature

The system comes in a variety of configurations:

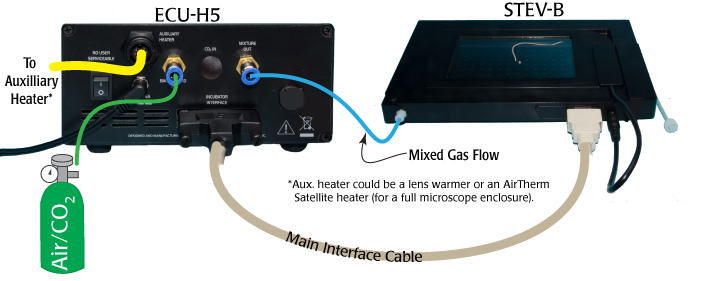

- IV-ECU-H5–Pre-mixed CO2 gas of the desired concentration is pumped into the system, and this ECU regulates the airflow at the desired level. It also controls the heating and monitors the environment chamber.

- IV-ECU-HC–This control unit mixes the air and CO2 gas to the desired concentration. An internal CO2 sensor (inside the ECU controller) monitors the concentration of the gas. The ECU-HC regulates the airflow at the desired level, controls the heating of the system and monitors the environment chamber.

- IV-ECU-HOC–This unit performs like the ECU-HC. In addition to controlling the temperature and CO2, this unit also controls the O2 level. However, it offers no auxiliary heating options. Nitrogen is used to displace oxygen from the background air, which generally has about 20.7% oxygen. The O2 level of the background gas can be regulated down to as low as 1%.

- IV-ECU-HCP–This unit performs like the ECU-HC, except this unit comes with a remote CO2 sensor that is positioned inside the stagetop environment chamber.

Satellite Heater Features

The optional Satellite AirTherm can be controlled by the ECU to regulate temperature in an incubation chamber. The 220V is pictured above.

- USB-based remote control and data logging

- Electronic flow meter

- Programmable alarm for out of tolerance condition

- Compact and lightweight

- Adjustable setpoints for parameters, including:

- Temperature PID controls for the environmental chamber with ±0.1ºC precision

- CO2 and O2 digital PID control with ±0.1% precision

- Airflow digital PID control from 0–900 SCCM

Setup Configuration

Specifications

| Operating Temperature (ambient) | 10 – 50°C (50 – 122°F) |

| Operating Humidity (ambient) | 15 – 70% RH, non-condensing |

| Warm up Time | 20 minutes |

| Computer Interface | USB via external USB/RS232 converter |

| Sensor | Non-dispersive infrared (NDIR), dual beam, 20s response time |

| Power | 110/240V, 50/60Hz |

| CO2 Sensor (ECU-HCP and ECU-HC only) Sensor Range | 0 – 20% CO2 |

| Control Range | 0 – 20% |

| Control Precision | 0.1% CO2 |

| Control Accuracy | 0.1 – 3% of reading |

| Drift | |

| O2 Sensor (ECU-HOC only) Sensor Type | Zirconium Dioxide, diffusion, 4s response time |

| Sensor Range | 0–25% |

| Control Range | 0–25%* |

| Control Precision | 0.1% |

| O2 Control Accuracy | ±0.5% (2% of the full scale) |

*The upper limit of the ECU-HOC oxygen control range is constrained by the oxygen content in the background gas. For example, if the background air has 20.7% oxygen, the ECU-HOC can only control up to 20.7% oxygen.

Accessories

Citations

RelatedItems

IV-ECU-H5

Stage top Environmental Chamber with Controller for heat, air flow from bottled gas

IV-ECU-HC

Stagetop Environment Chamber with Environmental Control Unit for CO2 and heat

IV-ECU-HCP

Stagetop Environment Chamber and Environmental Control Unit for CO2, O2 and heat, ex...

Request

Catalogue

Chat

Print