MS2

Perfusion of slice on both sides for upright microscope

- Overview

- Specifications

- Accessories

- Citations

- Related Products

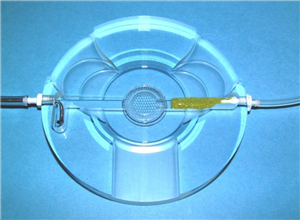

Overview

The MS2 is similar in construction to the MS1 chamber offering clearance for rotary and swing type microscope objective turrets. The central area has a #2 cover glass bottom with a 2 mm gap above it where a piece of replaceable nylon netting is trapped by a ’C’ ring (similar to BSC3 construction). Brain slices rest on the top of the nylon netting allowing both sides of the slice to be bathed with solution. The solution enters from one side and is passed through a buffer material to smooth out flow and exits via a slotted steel ‘L’ tube to aspirate out to a vacuum line. Flow rates from around 2ml/min and upwards keep the overall dead-space low for expensive drug exchanges. The chamber can be mounted on an upright microscope stage with normal condenser optics from below. Only the central 18 mm diameter area is flooded with solution contained within the ‘C’ ring above trapping the netting where the slice rests. The exit of solution is under the closed side of the ‘C’ ring so that fluid is made to flow over the slice and down to the exit channel. This ensures that the input solution path is both above and below the slice.

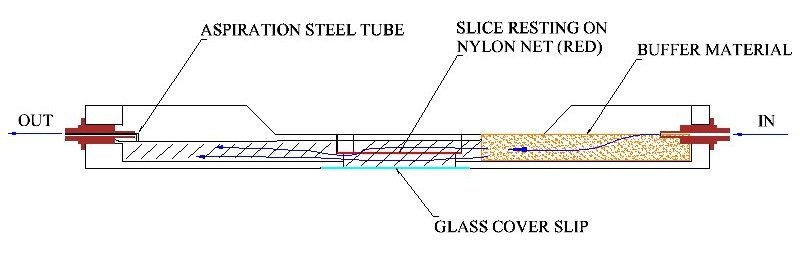

Schematic

Parts description

MS2 Slice chamber show in cross section. Slices rest on removable netting (RED) and perfusion solution enters via buffer material (nylon mesh) to one side. Solution enters both above and below slice but exits below the ‘C’ ring at the opposite end of the ‘C’ ring opening. A steel suction needle with a slot whose height is adjustable by turning sets the fluid level. Fluid is maintained constantly above the netting with a flow rate of up to 6ml/min and with a suction line attached to the exit needle.

Request

Catalogue

Chat

Print